Hydraulic Junttan Hammer

7.7.2021

Second part of our blog is dedicated to the story behind one of the main components of our company, the hydraulic impact hammer. As stated already in the first part of our blog, probably the biggest reason to start up the business was the need for reliable and more effective impact hammer and base machine. Old mechanical drop hammers were unreliable and slow, new ones were not really available and diesel operated hammers were not suitable for Finnish conditions. In the 1970’s hydraulic excavators were replacing old mechanical cable driven equipment and for Pentti Heinonen and his team at Savon Varvi, it felt natural that the impact hammer should also be operated with hydraulics because it was the modern way to build equipment. Even though the results and further developments in the following decades have been ground-breaking, and one of the biggest single reasons for Junttan’s success, the push to start developing the hammer came from a very practical incentive.

Late 70’s and early 80’s hydraulic earth-moving and construction equipment was a new thing in the market. Most of the companies were trying to develop hydraulic applications for their own purposes. Some companies succeeded well, while others struggled a lot. At Junttan (or still Savon Varvi at the time) we had the advantage of very high level of expertise from early hydraulic solutions and how to use them. Early days hydraulic rock drilling and dredging equipment and good understanding on the everyday life at work sites gave us a good starting point for the development. Therefore, it was very clear for Pentti Heinonen and Raimo Partanen from the beginning that the new pile driving equipment needed to be operated with hydraulics but also be safe and reliable, have high efficiency and get the concrete piles to the ground intact. This way they could combine the benefits from old diesel hammers and mechanical drop hammers and get rid of their weaknesses.

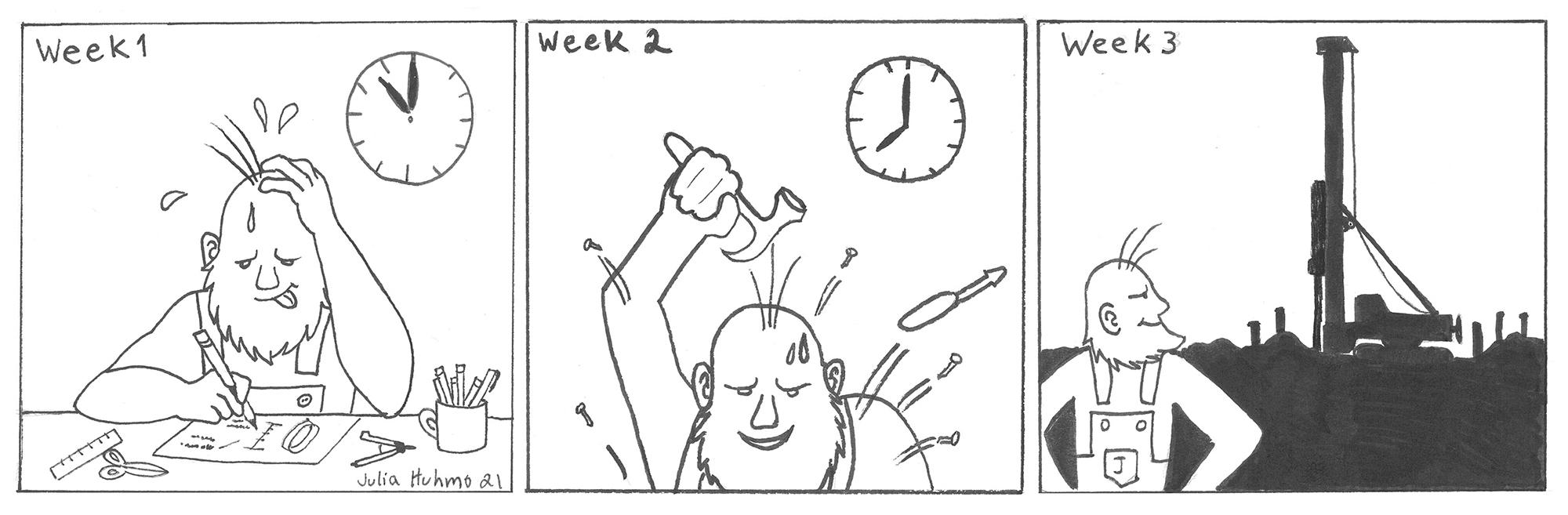

Equally important part in the development process was the cooperation with contractors. Ideas and experience from our own team was combined with feedback from the users of the equipment, usually on few days’ notice. The next version of the hammer was put to the test and performance was evaluated again. This way the equipment was constantly evolving and new features were added. The reputation of Junttan’s hydraulic hammers started to grow.

Own experiences and the contracting background always kept the high efficiency and best possible performance at the work site in the centre of attention. A concrete pile can only take a certain amount of impact energy and impact speed to remain intact. In order to build reliable and long-lasting foundations for long-lasting buildings and structures, we needed to focus on building a hammer that had even output for each blow, consistent speed to keep the pile “alive” while driving it and keep on doing it over and over again day after day. It is probably worth mentioning that the very first hammer that we ever built, already did 800 meters of piling per day on its first jobsite, without problems.

The first years of the development of purpose-built piling rigs and hydraulic hammers went pretty much hand in hand, complementing each other, even though the first free hanging hammer was delivered already in 1983. In the beginning both products needed a lot of attention and whatever issue was the most urgent, got bigger part of resources to solve it. Therefore, the biggest and most evolutionary invention actually came out as late as early 90’s. That was when the first accelerated hammers were built. The first prototype went to Singapore and second unit to MVR Hakala in Finland. During the years, the team behind the development of Junttan hammers, Raimo Partanen working as the mastermind behind it all, had already discovered many features that could be built in to the hammers and ways how the efficiency and speed could be developed even more, still keeping the piles in one piece and hammer working without need to worry about its durability. Long experience and numerous experiments, meticulous attention to details and studies with different prototypes, led to an invention where hydraulic flow could be directed precisely at the exact right time. That, combined with correct sized volume differences in the cylinder, created a hammer that can accelerate the ram block and still operate reliably. Countless tests and experiments, where parameters were changed almost at millisecond intervals, led to the discovery and allowed us to take next leap.

After the innovation of combination of accelerating piling cylinder and valve, our equipment has developed a lot, but the center innovation has remained very similar through the years. Some modifications have been necessary when, for example, more and more steel piling needed to be done and the need for bigger and smaller hammers arose. Modular structure of the hammer was a goal from the beginning. A hammer which size can be changed easily by the user, makes the life at work site easier and expands the opportunities for a single machine unit. Broad variety of accessories: drive caps for different sized piles, sheet piles, pile sleeves for free hanging purposes or hydraulic power packs that enable the use in a big spotter leader for crane and free hanging use, make Junttan hammers an easy choice for all driven piling.

During the decades, after the first hammers and development of first accelerated hammers, piling as work method has evolved a lot: concrete piles and steel piles are driven mostly with equipment dedicated for that specific task, sizes of steel piles have increased, ram block weights and needed impact energy have raised. More and more automatic functions and smart user interfaces are needed and environmental issues demand new solutions to reduce noise and emissions. Junttan has done a lot to meet these changes and we continue to develop solutions for future needs.

Even though the outcome, Junttan hydraulic hammer with its broad modifications and models, has had a significant role in our success, the reason behind was basically just a quick decision to solve an issue that needed to be solved. It was the meticulous study and learning from users’ experiences that eventually led into the final big breakthrough. Therefore it is still very important for us today to remember our roots and in a way pay a tribute to the forefathers of all this by continuing the learning process by listening to our customers and trying new things with an open mind.

To underline the meaning of experience and devotion, let’s finish the story with a funny memory from few years back. A Junttan representative was attending a piling seminar and was also taking part in a panel discussion at the end of the day. Somebody from the audience made a note that they are having huge problems with a hydraulic hammer they are using (this was not a Junttan hammer). Hammer kept breaking because it started to lift the ram block too early and the valves couldn’t be adjusted. It was a true nightmare to use the hammer. Member of the audience continued and asked the Junttan representative: “Do these problems sound familiar to you? Are you sure that your equipment works?”. Junttan representative replied: “Yes, it sounds familiar. We had those same problems 30 years ago”.

More Blogs

Hydraulic Junttan Hammer

Second part of our blog is dedicated to the story behind one of the main components of our company, the...

7.7.2021

Junttan Piling Blog – Junttan’s 45th Anniversary Year

This year, 2021, marks the 45th anniversary of Junttan Oy. During the last 4 decades, when we have been building piling...

18.5.2021